Table of Contents

Overview of Loncin 764CC Gasoline Engine

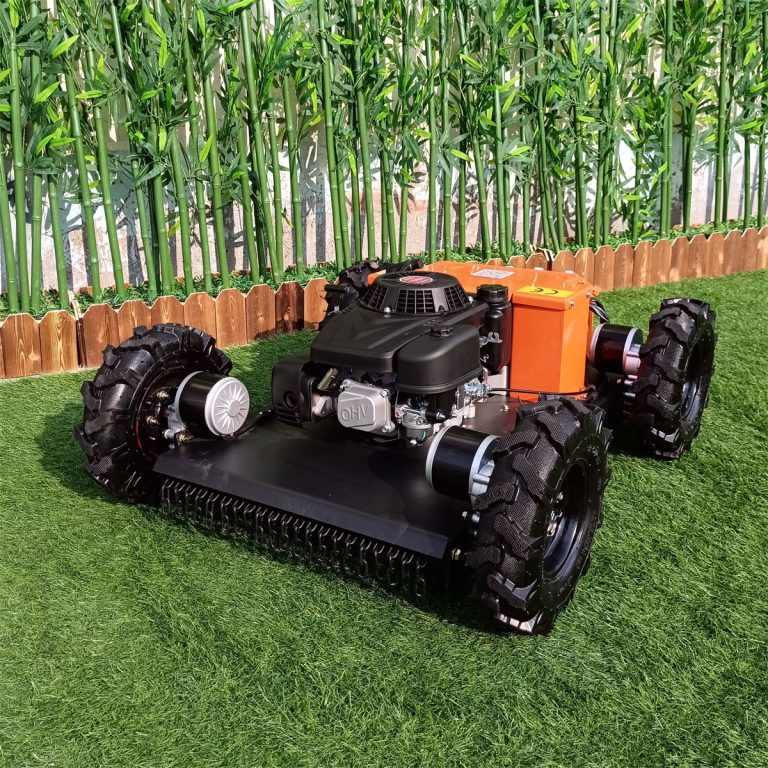

The Loncin 764CC gasoline engine is a remarkable feature of the unmanned brush mulcher, providing exceptional power and reliability for various applications. This powerful engine is designed with V-type twin-cylinder technology, delivering a rated power of 18 kW at 3600 rpm. This performance capability ensures that the machine can tackle even the toughest vegetation management tasks with ease. Equipped with the Loncin brand, model LC2V80FD twin-cylinder gasoline engine, the mulcher showcases strong performance, making it an ideal choice for both professional and commercial users. The engine’s design includes a clutch that engages only when the engine reaches a predetermined rotation speed, ensuring efficient operation and reduced wear on components.

Equipped with the Loncin brand, model LC2V80FD twin-cylinder gasoline engine, the mulcher showcases strong performance, making it an ideal choice for both professional and commercial users. The engine’s design includes a clutch that engages only when the engine reaches a predetermined rotation speed, ensuring efficient operation and reduced wear on components.

The robust construction of the Loncin 764CC gasoline engine translates into impressive output, allowing the unmanned brush mulcher to maintain a travel speed of 4 Km. This feature enhances productivity while ensuring that operators can cover large areas without compromising power.

The robust construction of the Loncin 764CC gasoline engine translates into impressive output, allowing the unmanned brush mulcher to maintain a travel speed of 4 Km. This feature enhances productivity while ensuring that operators can cover large areas without compromising power.

Features and Safety Mechanisms

The unmanned brush mulcher stands out with its advanced safety mechanisms and innovative features. It is powered by two 48V 1500W servo motors, providing substantial climbing ability and strong performance across various terrains. A built-in self-locking function guarantees that the machine only moves when both power is on and throttle is applied, preventing unintended movement and significantly enhancing operational safety.

The unmanned brush mulcher stands out with its advanced safety mechanisms and innovative features. It is powered by two 48V 1500W servo motors, providing substantial climbing ability and strong performance across various terrains. A built-in self-locking function guarantees that the machine only moves when both power is on and throttle is applied, preventing unintended movement and significantly enhancing operational safety.

With a high reduction ratio, the worm gear reducer amplifies the torque generated by the servo motors, offering immense output torque that aids in climbing steep slopes. Notably, in a power-off state, the friction between the worm and gear provides mechanical self-locking, safeguarding against sliding downhill during power loss.

The intelligent servo controller further elevates the operational efficiency of the mulcher by precisely regulating motor speed and synchronizing the left and right tracks. This smart design enables the mower to travel in a straight line without constant adjustments, minimizing operator workload and reducing risks associated with over-correction on inclines.

With a high reduction ratio, the worm gear reducer amplifies the torque generated by the servo motors, offering immense output torque that aids in climbing steep slopes. Notably, in a power-off state, the friction between the worm and gear provides mechanical self-locking, safeguarding against sliding downhill during power loss.

The intelligent servo controller further elevates the operational efficiency of the mulcher by precisely regulating motor speed and synchronizing the left and right tracks. This smart design enables the mower to travel in a straight line without constant adjustments, minimizing operator workload and reducing risks associated with over-correction on inclines.